A comprehensive guide to professional golf umbrella manufacturing from Topumbrella

Introduction – What Makes a Professional Golf Umbrella Factory

Golf umbrellas are not your ordinary rain protection devices. These oversized canopies, typically spanning 60 to 68 inches in diameter, are engineered to withstand challenging weather conditions on the golf course while providing ample coverage for both golfers and their equipment. The defining characteristics of a professional golf umbrella include large-scale construction, superior wind resistance through reinforced framework and vented canopy designs, and most importantly, the ability to showcase brand logos and custom designs that meet the exacting standards of global brands.

As a leading golf umbrella factory with dual manufacturing bases, Topumbrella combines the technical expertise and manufacturing efficiency of our China facility with the export advantages of our Cambodia operation. This strategic positioning allows us to serve as a trusted OEM umbrella factory for international brands seeking both quality and competitive pricing. Our dual-base model offers clients the best of both worlds: decades of Chinese manufacturing experience paired with Cambodia's preferential trade agreements and tariff-free export opportunities to major markets including the United States and European Union.

Operating as a specialized custom golf umbrella manufacturer, we've refined our production processes to deliver consistent quality across thousands of units. Our facilities are equipped with modern machinery, experienced craftspeople, and rigorous quality control systems that ensure every umbrella meets international standards. Whether you're a premium golf brand seeking luxury umbrellas with intricate details or a corporate client needing volume production with consistent branding, our manufacturing capabilities are designed to accommodate diverse requirements while maintaining the highest quality standards throughout every production stage.

Key Factory Advantages: Dual-base production (China + Cambodia) | Full OEM/ODM capabilities | BSCI & ISO certified | Sustainable material options | Brand customization expertise

Step 1 – Fabric Preparation and Cutting

Cutting machine at Topumbrella manufacturing facility

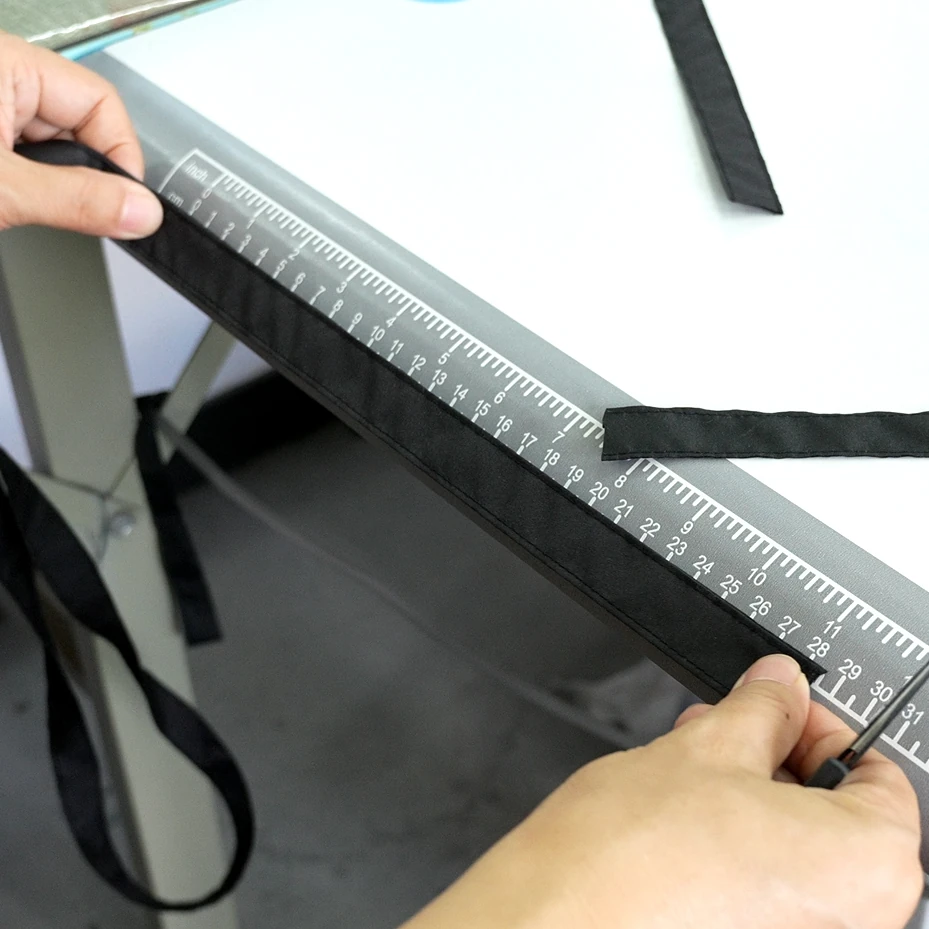

Precision fabric slitting operation at Topumbrella manufacturing facility

The foundation of any quality golf umbrella begins with meticulous fabric preparation. Our umbrella fabric cutting process starts with large rolls of premium canopy material, which arrive at our facility after stringent material inspection. The fabrics we work with range from traditional polyester to advanced performance materials like RPET (recycled polyester) and specialized waterproof-breathable composites designed specifically for golf umbrella material applications.

Fabric Slitting (measured by yard): This initial stage involves running large fabric rolls through precision slitting machines that cut the material into specific widths required for umbrella panel production. The slitting width varies depending on the umbrella design specifications, typically ranging from 8 to 12 inches for standard golf umbrellas. Our automated slitting equipment ensures consistent width measurements across thousands of yards, eliminating the material waste that often occurs with manual cutting methods. The precision at this stage is critical because even minor width variations can compound during assembly, resulting in improperly balanced canopies.

Overlocking (measured by yard): Immediately following the slitting process, each fabric strip undergoes overlocking—a specialized edge-finishing technique that prevents fraying and unraveling. Industrial overlock machines apply reinforced stitching along both edges of the fabric strips, creating a durable hem that will withstand the stress of wind exposure and repeated opening and closing cycles. This step is particularly crucial for golf umbrellas, which experience significantly more mechanical stress than standard rain umbrellas due to their larger size and exposure to windy golf course conditions. The overlocking thread is carefully color-matched to the canopy fabric or, in some cases, selected as a contrasting design element per brand specifications.

Panel Cutting (measured by piece): With properly prepared fabric strips, we proceed to panel cutting—the transformation of linear fabric into the distinctive triangular or curved segments that form the umbrella canopy. Using computer-guided cutting tables or die-cutting presses, we achieve precise angles and dimensions for each panel. A typical golf umbrella requires 8 to 16 individual panels, depending on the design. Each panel must be cut with exact geometric precision because the cumulative effect of all panels determines whether the finished canopy will open to a perfect circle or dome shape. Modern golf umbrellas often feature alternating color panels or complex pattern layouts, requiring additional precision in the cutting stage to ensure proper pattern alignment during assembly. Our cutting stations are equipped with vacuum hold-down systems that keep fabric perfectly flat during cutting, preventing the material distortion that can occur with manually held fabrics.

Technical Highlight: Our automated cutting systems reduce material waste by 15-20% compared to manual cutting, while maintaining tolerances within ±1mm for panel dimensions—critical for achieving perfect canopy symmetry in large golf umbrellas.

Step 2 – Sewing and Assembly Process

Skilled technicians performing precision panel sewing for wind-resistant construction

The sewing stage represents where raw materials transform into functional canopy assemblies. This is where the artistry of umbrella manufacturing truly shines, combining industrial sewing technology with skilled craftsmanship. Our umbrella sewing process encompasses multiple specialized operations, each contributing to the durability, aesthetics, and performance of the finished golf umbrella.

Ruffles Sewing : Decorative ruffles or piping along panel edges serve both aesthetic and functional purposes. These sewn embellishments add visual interest while reinforcing the structural integrity of panel seams. Using industrial sewing machines configured for decorative stitching, our operators apply consistent ruffle patterns that enhance the umbrella's premium appearance. This detail is particularly important for luxury golf umbrellas where visual refinement differentiates premium products from economy alternatives.

Strap Sewing : The umbrella strap—often overlooked but essential for functionality—is attached during this phase. We sew heavy-duty straps that allow golfers to secure the closed umbrella conveniently. Strap placement is carefully calculated to ensure balanced carrying when the umbrella is closed. The attachment points are reinforced with bartack stitching (multiple layers of dense stitching) to withstand years of repeated use. For branded golf umbrellas, straps often incorporate woven or printed logos, requiring precise alignment during the sewing process.

Umbrella strap measurement

Umbrella strap sewwing

Velcro or Snap Attachment : The umbrella strap closure system receives careful attention during finishing operations. We attach either hook-and-loop (Velcro) closures or snap buttons according to client preferences and umbrella styling. Velcro offers infinite adjustability and secure closure, while snaps provide a cleaner aesthetic appearance and distinctive closure sound. The fastener placement is calculated to hold the closed umbrella securely without excessive tightness that could stress the canopy or frame. High-quality fastener materials ensure reliable function through hundreds of opening cycles without degradation.

Velcro Umbrella strap sewwing

Panel Sewing : This is the critical stage of golf umbrella assembly where individual panels are joined to create the complete canopy. The umbrella panel stitching technique directly impacts the umbrella's wind resistance and water-shedding performance. Our sewers use specialized umbrella sewing machines with modified presser feet designed to handle the bulk of multiple fabric layers converging at panel seams. Each seam is double-stitched for strength, with seam allowances carefully controlled to prevent puckering or gathering that would compromise the canopy's smooth opening action. The panel assembly follows a specific sequence—typically starting with pairs of panels that are then joined into quarters, then halves, and finally the complete canopy circle. This progressive assembly approach ensures even tension distribution across all seams.

Cover Sewing : Simultaneously with canopy assembly, a separate production line manufactures the protective covers that accompany most golf umbrellas. These covers must accommodate the umbrella's closed dimensions while providing easy insertion and removal. We sew covers with reinforced openings, elastic closures or drawstrings, and branded labels as specified by clients. The cover material is selected to complement the umbrella's aesthetic while providing durable protection during storage and transport.

The quality of panel sewing cannot be overstated in its impact on umbrella performance. Poorly executed seams create weak points where wind pressure can cause panel separation or canopy inversion. Our sewing department operates under strict quality protocols, with inline inspections verifying stitch density (typically 10-12 stitches per inch for golf umbrellas), seam straightness, and proper seam finishing. Additionally, our sewers are trained in the specific considerations of waterproof canopy construction—techniques such as taped seams or specialized stitching patterns that minimize water penetration through needle holes.

Quality Insight: Our sewing technicians undergo specialized training in golf umbrella construction techniques, including advanced seam reinforcement methods that increase wind resistance by up to 30% compared to standard umbrella sewing approaches.

Step 3 – Canopy Inspection and Frame Integration

Comprehensive quality inspection before frame integration

Before the sewn canopy can be united with its structural framework, it must pass through rigorous inspection protocols. This intermediary quality control stage prevents defective canopies from advancing to expensive frame assembly, where corrections become significantly more costly and time-consuming.

Canopy Inspection (measured by piece): Every sewn canopy undergoes detailed visual and dimensional inspection. Quality control personnel examine the canopy spread on illuminated inspection tables, checking for numerous potential defects including fabric flaws (pulls, stains, color inconsistencies), stitching irregularities (skipped stitches, tension problems, misaligned seams), dimensional accuracy (proper radius measurements, panel symmetry), and pattern alignment (for multi-color or printed designs). Inspectors use specialized templates and measuring tools to verify that each canopy meets the exact specifications required for its intended frame size. Any canopy failing inspection is tagged for rework or rejection, depending on the nature and severity of the defect.

While canopy inspection occurs, parallel production lines are preparing the golf umbrella frame components. Premium golf umbrellas typically feature fiberglass ribs for flexibility and wind resistance, steel or aluminum shafts for strength and stability, and precisely engineered opening mechanisms (manual, automatic, or double-automatic systems). The frame components arrive at our assembly stations as pre-manufactured sub-assemblies, having undergone their own quality verification processes to ensure proper dimensions, smooth mechanical operation, and corrosion-resistant finishes.

Top Stitching / Belt Sewing : The marriage of canopy to frame begins at the umbrella's crown—the central hub where all ribs converge. Skilled assembly workers carefully align each rib tip with its corresponding canopy panel pocket or channel. The canopy is then secured to the rib tips through various attachment methods depending on umbrella design: sewn pockets that encase the rib tips, plastic or metal tip caps that clamp the fabric, or tie-on systems using cords threaded through canopy grommets. This attachment process requires precision to ensure even tension distribution across all panels when the umbrella is opened. Uneven tension causes asymmetric opening patterns and places undue stress on certain ribs, leading to premature failure.

Following rib attachment, the canopy undergoes belt sewing at the runner—the sliding mechanism that travels up and down the shaft to open and close the umbrella. The canopy's inner edge is carefully sewn or secured to the runner's notch positions, again maintaining equal tension across all attachment points. This stage of umbrella shaft assembly is critical because improper runner attachment can cause binding during the opening mechanism's travel or create loose spots that flutter and tear in wind.

The fully integrated canopy-frame assembly then undergoes functional testing. Technicians manually operate the opening mechanism through multiple cycles, verifying smooth operation, proper locking engagement, and symmetric canopy deployment. The assembled umbrella is examined for proper frame alignment—when opened, the umbrella should form a smooth dome without warped ribs or uneven canopy surfaces. Any mechanical issues detected at this stage trigger disassembly and correction before the umbrella advances to finishing operations.

Manufacturing Excellence: Our frame integration specialists achieve a first-pass assembly success rate exceeding 95%, minimizing rework and ensuring consistent mechanical performance across production runs.

Step 4 – Branding and Accessories

Professional logo application and custom branding services

For golf umbrellas serving promotional or branded purposes, the application of logos and finishing details transforms a functional product into a powerful marketing tool. As a specialized OEM umbrella branding facility, Topumbrella offers comprehensive customization services that allow clients to achieve their exact brand presentation requirements.

Custom Logo Application: We employ multiple printing and decoration techniques suitable for custom golf umbrella logo placement, each selected based on design complexity, color requirements, production volume, and budget considerations. Screen printing remains the most cost-effective method for simple logos with limited colors, delivering crisp, opaque prints that withstand weather exposure. For photographic quality or gradient designs, we utilize heat transfer printing or digital direct-to-fabric printing technologies that reproduce complex artwork with exceptional detail. Embroidery represents the premium decoration option, creating dimensional logos with superior durability and a luxury tactile quality that resonates with high-end brands.

Logo placement strategy varies by brand objectives. Common positions include prominent placement on one or more canopy panels (ideal for maximum visibility when the umbrella is open), shaft imprints or handle branding (maintaining brand presence when closed), and decorative elements like branded runner caps or custom handle designs. Our graphics department works closely with clients during the design phase to optimize logo sizing, positioning, and color specification for maximum visual impact while respecting the umbrella's overall aesthetic balance.

As specialists in umbrella accessories, we also coordinate the sourcing and attachment of various optional enhancements that elevate golf umbrellas beyond basic functionality. These may include ergonomic rubber grip handles, automatic opening buttons with branded detailing, vented canopy designs with coordinating color inserts, reflective piping or trim for visibility, carrying cases with embroidered logos, and hang loops or wrist straps for convenient transport. Each accessory integration is executed with the same attention to quality and brand consistency that defines our core manufacturing process.

Customization Capabilities: Our in-house graphics team and decoration department enable rapid prototyping and sampling, with typical turnaround of 7-10 days for branded samples and 30-45 days for production runs of 1,000+ units.

Step 5 – Quality Control and Final Inspection

Quality Control and Final Inspection

Quality Control and Final Inspection

Quality assurance represents not merely a checkpoint but rather an integrated philosophy permeating every stage of our manufacturing process. However, the final inspection stage serves as the ultimate gatekeeping function, ensuring that only umbrellas meeting our rigorous standards reach our clients. This comprehensive golf umbrella quality control system reflects our commitment to manufacturing excellence and brand reputation protection.

Umbrella Stitching Final Verification (measured by piece): Even though stitching quality has been monitored throughout assembly, the completed umbrella undergoes a thorough examination of all sewn components. Inspectors examine every seam connection, strap attachment, logo application, and decorative element for consistency with specifications. They verify proper thread tension (neither too tight nor too loose), adequate seam allowances, secure bartack reinforcements at stress points, and absence of loose threads or incomplete stitches. This granular inspection catches any defects that might have escaped detection during inline quality checks.

Final Inspection (measured by piece): The comprehensive umbrella inspection process evaluates both cosmetic and functional aspects of each finished umbrella. Quality control personnel conduct systematic examinations covering dimensional verification (opened diameter, closed length, canopy depth), mechanical function testing (opening/closing mechanism smoothness, locking reliability, proper frame alignment), aesthetic assessment (color matching, print quality, fabric appearance, symmetry), and brand compliance verification (logo accuracy, placement correctness, accessory specifications).

Functional testing is particularly rigorous for golf umbrellas given their performance-critical applications. Each umbrella undergoes multiple opening and closing cycles to verify mechanism durability and detect any binding, hesitation, or mechanical irregularity. The opened umbrella is examined for proper canopy tensioning—the fabric should be taut without excessive strain, forming a smooth dome shape without wrinkles or loose areas. Frame alignment is assessed by observing the umbrella from multiple angles to ensure all ribs deploy to equal positions, creating a symmetric canopy circle.

Wind resistance testing represents a critical evaluation for golf umbrellas. While full wind tunnel testing is typically reserved for product development, our final inspection includes manual stress testing where inspectors apply controlled force to simulate wind pressure on the opened canopy. This test reveals whether the frame construction and canopy attachment can withstand typical wind conditions without inverting, bending, or sustaining damage. Premium golf umbrellas featuring vented canopy designs undergo additional testing to verify that the vents function properly—releasing excess wind pressure while maintaining weather protection.

Rework Process (measured by piece): Umbrellas failing final inspection are not automatically rejected but instead channeled to our rework department for evaluation and potential correction. Minor defects such as loose threads, missing decorative elements, or small stitching irregularities can typically be corrected through targeted repairs. The rework team consists of experienced technicians skilled in surgical corrections that bring defective units into compliance without compromising structural integrity or aesthetic appearance. Each repaired umbrella must pass through final inspection again before approval for shipment. Only umbrellas with irreparable defects (major frame damage, extensive fabric flaws, incorrect specifications that cannot be modified) are rejected as scrap.

Our quality management system operates under internationally recognized standards. As a BSCI umbrella factory, we maintain compliance with the Business Social Compliance Initiative, demonstrating our commitment to ethical manufacturing practices, safe working conditions, and environmental responsibility. Our facilities hold ISO 9001 certification for quality management systems, providing clients with confidence in our process consistency and continuous improvement culture. We regularly host third-party audits from SGS and other internationally recognized inspection agencies, maintaining transparent operations that meet the scrutiny of quality-conscious global brands.

Quality Metrics: Our final inspection process maintains a defect rate below 0.5% for shipped products, with comprehensive documentation and traceability systems enabling rapid response to any quality concerns that may arise post-shipment.

Professional In-house Testing Laboratory

Explore our latest info page to learn more about quality umbrella design, features, and innovation.

Learn MoreStep 6 – Packaging and Shipping

Professional packaging and export preparation at our dual-base facilities

Professional packaging and export preparation at our dual-base facilities

The final manufacturing stage transforms approved umbrellas into protected, properly identified, and shipping-ready products. Our umbrella packaging operations combine protection requirements with presentation considerations, ensuring that umbrellas arrive at their destinations in pristine condition while meeting any specific packaging requirements mandated by clients or retail channels.

Packaging Process (measured by piece): Each umbrella receives multi-layer packaging suited to its destination and intended use. The basic packaging sequence begins with securing the closed umbrella with its attached strap, followed by insertion into its protective fabric or vinyl cover (if included). Individual umbrellas are then wrapped in poly bags to prevent moisture damage and dust accumulation during transit. For retail-destined umbrellas, custom-printed sleeves or hang tags are applied at this stage, displaying brand information, product specifications, barcodes, and any required regulatory markings.

Multiple individually packaged umbrellas are then organized into master cartons—corrugated shipping boxes designed to protect contents during the rigors of international freight transport. Our packaging engineers calculate optimal carton configurations that maximize shipping container utilization while providing adequate cushioning against impacts. Typical golf umbrella master cartons contain 12-36 units depending on umbrella size and packaging specifications. Each carton is clearly labeled with client information, product codes, quantity counts, and destination details. For shipments requiring specific warehouse handling or distribution center compliance, we apply appropriate logistics labels, RFID tags, or retailer-specific markings as directed.

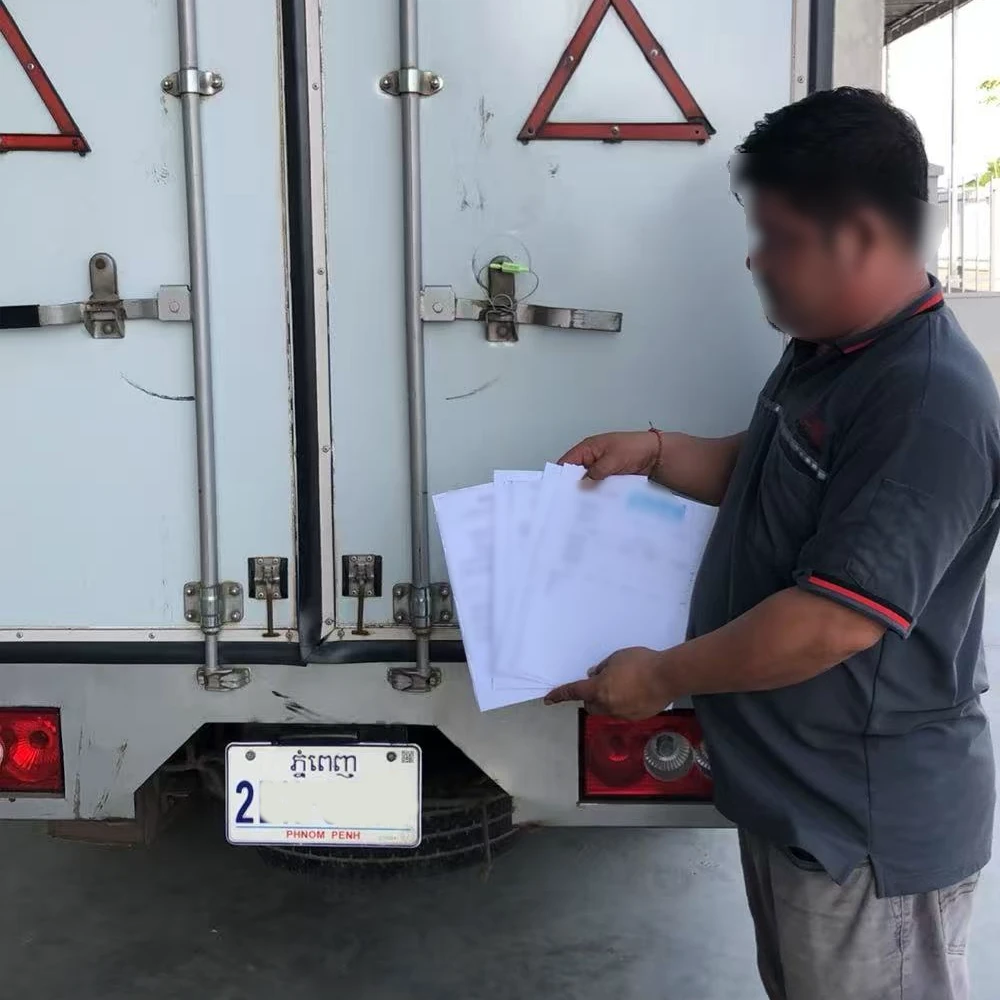

Export documentation preparation runs parallel to physical packaging operations. Our logistics team generates commercial invoices, packing lists, certificates of origin, and any required compliance documentation (such as safety certifications or material composition declarations). This documentation package accompanies the shipment and enables smooth customs clearance at destination ports. Our experience with international golf umbrella export procedures ensures that documentation accuracy and completeness eliminate delays and additional charges that can occur with improperly prepared shipments.

The strategic advantage of our dual-base manufacturing model becomes particularly evident during the shipping phase. Our Cambodia umbrella factory provides significant benefits for clients shipping to markets where Cambodia enjoys preferential trade status. Under various trade agreements including the Generalized System of Preferences (GSP) and specific bilateral agreements, products manufactured in Cambodia often qualify for reduced or zero tariff rates when imported into the United States, European Union, Canada, Japan, and other major markets. This tariff advantage can translate to substantial cost savings, particularly for large-volume orders, making our Cambodia-manufactured umbrellas more competitive in price-sensitive markets while maintaining the same quality standards as our China facility.

Container loading represents the final physical handling stage. Our shipping staff carefully loads master cartons into 20-foot or 40-foot shipping containers (or smaller LCL consolidations for partial container loads), maximizing space utilization while ensuring proper weight distribution and load security. Cartons are stacked systematically with heavier boxes at the bottom, appropriate void filling to prevent shifting during transit, and photographic documentation of the loading process for reference. A typical 40-foot high-cube container can accommodate approximately 10,000-15,000 golf umbrellas depending on size and packaging specifications—representing significant economies of scale for large orders.

Our logistics coordination extends beyond the factory gate. We maintain relationships with reliable freight forwarders and shipping lines, enabling us to offer competitive freight rates and flexible shipping options including sea freight (most economical for large volumes), air freight (for urgent orders or samples), and express courier services (for prototypes and small quantities). Our dual-base operation provides shipping flexibility—clients can choose to manufacture in China with its extensive supplier ecosystem and infrastructure, or in Cambodia to leverage tariff advantages, depending on their specific cost and timing priorities.

Lead time management represents a critical component of our service offering. Standard production timelines for golf umbrellas range from 30-45 days for orders of 1,000-5,000 units, with shorter timelines available for rush orders (potentially 20-25 days with premium charges) and longer timelines typical for complex customizations or very large volumes exceeding 20,000 units. Our China facility typically offers faster turnaround due to proximity to component suppliers, while our Cambodia facility may require slightly extended timelines for certain specialized materials but compensates with significant tariff savings on the back end.

Logistics Advantage: Our dual-base model offers strategic flexibility—manufacture in China for speed and complexity, or in Cambodia for tariff-free export to major markets. Both facilities maintain the same rigorous quality standards while optimizing cost and delivery timelines.

Why Global Brands Choose Topumbrella

In an increasingly competitive marketplace where quality, cost, and ethical manufacturing practices all factor into sourcing decisions, Topumbrella has emerged as a preferred partner for international brands seeking reliable OEM golf umbrella manufacturing. Our value proposition extends beyond basic production capabilities to encompass comprehensive solutions that address the multifaceted challenges brands face in umbrella procurement.

Dual-Base Production Advantage: Our strategic operation of manufacturing facilities in both China and Cambodia represents more than geographic diversification—it's a deliberate response to the evolving dynamics of global trade. The China facility leverages decades of accumulated manufacturing expertise, access to the world's most comprehensive umbrella component supply chain, and proximity to innovation in materials and mechanisms. This base excels in complex customizations, rapid prototyping, and products requiring specialized materials or intricate construction details that benefit from China's unmatched manufacturing ecosystem.

Conversely, our Cambodia facility capitalizes on that nation's preferential trade status with major importing markets. Products manufactured in Cambodia and exported to the United States, European Union, United Kingdom, Canada, Australia, and Japan often qualify for reduced or zero tariff rates under various preferential trade programs. For brands importing large volumes, these tariff savings can amount to 6-15% of product value—substantial cost reductions that enhance competitive positioning or margin protection. Importantly, our Cambodia facility doesn't represent a compromise in quality; we've replicated the same equipment, training protocols, and quality systems from our China operation, ensuring consistent output regardless of manufacturing location.

Comprehensive Customization Capabilities: As a specialized custom umbrella supplier, we understand that off-the-shelf products rarely meet the specific requirements of brand marketing, retail positioning, or promotional campaigns. Our customization services encompass every aspect of umbrella design and decoration. Logo application methods include screen printing, heat transfer, digital printing, embroidery, and laser engraving—each technique suited to particular design requirements, material combinations, and budget parameters. We work with brand teams and design agencies to optimize logo presentation, ensuring that brand identity translates effectively to the three-dimensional, functional canvas of an umbrella canopy.

Beyond graphics, we offer structural customization including canopy diameter selection (ranging from compact 54-inch models to expansive 68-inch tournament sizes), rib count and configuration (6-rib economy to 16-rib premium constructions), frame material selection (steel for economy, fiberglass for flexibility, aluminum for lightweight premium), opening mechanism choice (manual, semi-automatic, full-automatic), handle design options (straight, curved, ergonomic grips, custom molded handles), and color selection across virtually any Pantone specification for both canopy fabric and trim components.

Sustainability and Environmental Responsibility: Modern brands increasingly prioritize environmental credentials in their supply chains, and umbrella procurement is no exception. As a forward-thinking sustainable umbrella manufacturer, Topumbrella has invested in eco-friendly material options and production processes that align with corporate sustainability commitments. We offer RPET (recycled polyester) canopy fabrics manufactured from post-consumer plastic bottles—typically diverting 8-12 bottles per umbrella from landfills while delivering performance characteristics equivalent to virgin polyester.

For brands concerned about fluorinated chemicals, we provide PFAS-free waterproof treatment options. Traditional water-repellent treatments often relied on perfluorinated compounds (PFAS), which have raised environmental and health concerns. Our alternative treatments achieve excellent water-shedding performance using PFAS-free chemistry, allowing brands to market their umbrellas as environmentally responsible without compromising functional performance. Additionally, we've implemented waste reduction initiatives throughout our manufacturing process, including fabric cutting optimization to minimize scrap, recycling programs for production waste, and energy-efficient equipment upgrades that reduce our carbon footprint.

Technical Expertise and Product Development Support: Many brands lack in-house umbrella engineering expertise, making them reliant on manufacturing partners not just for production but also for product development guidance. Our technical team includes experienced umbrella engineers who can advise on design optimization, material selection for specific performance requirements, mechanism selection based on target price points and user preferences, and structural modifications to achieve particular aesthetic or functional goals. We maintain sample rooms with hundreds of umbrella variations, allowing clients to physically examine different construction approaches, material combinations, and finishing options before committing to production specifications.

Scalability and Production Flexibility: Whether clients require small runs of 500 units for corporate gifts or massive campaigns exceeding 50,000 units for retail distribution, our production capacity and flexibility accommodate diverse volume requirements. Our minimum order quantities are structured to be accessible for smaller brands and test marketing campaigns, while our peak production capacity can handle the demands of major retail launches without compromising delivery timelines. This scalability is particularly valuable for brands experiencing growth—they can start with modest orders and expand volumes as programs prove successful, confident that their manufacturing partner can scale alongside their needs.

Key Differentiators:

- Dual manufacturing bases in China and Cambodia for optimal cost and logistics

- Complete OEM/ODM services from concept to delivery

- BSCI & ISO certified operations ensuring ethical and quality manufacturing

- Sustainable material options including RPET and PFAS-free treatments

- Advanced branding capabilities with multiple logo application methods

- Flexible MOQs accommodating both corporate and retail programs

- Technical expertise supporting product development and optimization

- Comprehensive quality control with defect rates below 0.5%

Our Commitment to Quality, Responsibility, and Sustainability

Discover how Topumbrella integrates sustainability, quality, and innovation in umbrella manufacturing.

Learn More →Conclusion – From Fabric to Fairway

The journey of a golf umbrella from raw materials to finished product represents a complex orchestration of specialized processes, skilled craftsmanship, and rigorous quality control. As this comprehensive exploration of our manufacturing process reveals, producing professional-grade golf umbrellas demands far more than simply attaching fabric to a frame. Each stage—from precision fabric cutting and expert sewing to frame integration, branding application, quality verification, and protective packaging—contributes essential value to the final product that golfers rely upon for weather protection and that brands depend upon for marketing impact.

At Topumbrella, we've refined these processes over years of dedicated focus on umbrella manufacturing, continually investing in equipment upgrades, workforce training, quality system enhancements, and sustainable practices that keep us at the forefront of the industry. Our dual-base manufacturing model in China and Cambodia represents strategic positioning that delivers tangible advantages to our clients—combining manufacturing excellence with cost optimization through tariff benefits, while maintaining consistent quality standards across both facilities.

For global brands evaluating umbrella manufacturing partners, the decision extends beyond unit price considerations to encompass reliability, quality consistency, customization capabilities, ethical manufacturing practices, and logistical flexibility. Our track record serving international brands across diverse market segments—from premium golf equipment companies to corporate promotional buyers to retail chains—demonstrates our ability to adapt to varying requirements while maintaining the manufacturing excellence that protects brand reputations.

The umbrella industry continues evolving with emerging materials, innovative mechanisms, and heightened sustainability expectations. Topumbrella remains committed to leading these advancements, investing in research and development of eco-friendly materials, exploring automation technologies that enhance precision while maintaining employment, and expanding our customization capabilities to meet increasingly sophisticated brand requirements. Whether you're launching a new golf umbrella line, seeking a more reliable manufacturing partner, or exploring sustainable alternatives to current products, our team brings the expertise, capacity, and commitment to transform your vision into tangible products that perform exceptionally from the first fairway to the final green.

About Topumbrella

Learn more about our history, factory, and commitment to high-quality umbrella manufacturing across China and Cambodia.

Learn More →Ready to Start Your Custom Golf Umbrella Project?

Partner with Topumbrella for professional OEM golf umbrella manufacturing. Our team is ready to discuss your requirements, provide technical guidance, and deliver samples that showcase our quality and customization capabilities.

👉 Contact Our Factory for OEM Golf Umbrella ProductionGet a quote within 24 hours | Sample development in 7-10 days | Production capacity up to 50,000+ units monthly