Excellence Through Rigorous Testing

As a professional high-end umbrella manufacturing facility, Topumbrella established our in-house professional testing laboratory for two crucial reasons. First, outsourcing to external testing companies was significantly slowing our production cycle—testing processes typically required 1-2 weeks, severely impacting our efficiency and ability to serve our customers promptly. Second, our IQC (Incoming Quality Control) team needed immediate access to professional equipment to test every batch of incoming materials and finished products. Based on these testing results, we make critical decisions about material acceptance or rejection, ensuring only the highest quality components enter our production line.

Our advanced rain simulation chamber recreates various precipitation conditions, from light drizzle to heavy downpours. We test water penetration resistance, canopy drainage efficiency, and handle grip performance under wet conditions. This comprehensive testing is what sets professional umbrella suppliers apart from basic manufacturers and helps answer the question "which company is best for umbrellas?" when it comes to weather protection.

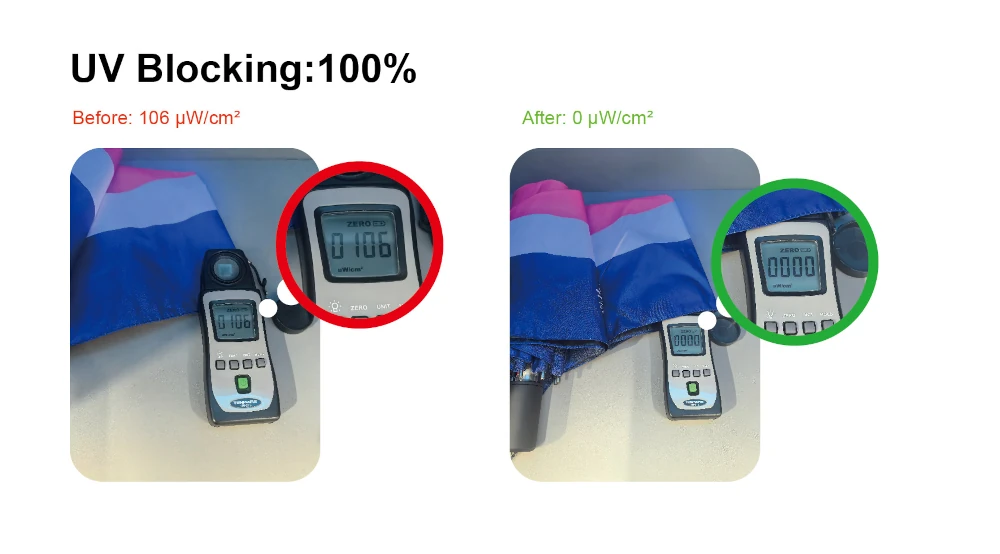

Using calibrated UV lamps that simulate intense sunlight, we measure the UV protection factor (UPF) of our umbrella fabrics. Our testing evaluates both UVA and UVB radiation blocking capabilities, ensuring our umbrellas provide superior sun protection. We also test for fabric degradation and color fastness under prolonged UV exposure.

Our corrosion resistance testing exposes metal components to salt spray and humidity chambers that simulate years of coastal weather exposure. We evaluate the performance of our anti-corrosion coatings and treatments on ribs, spokes, and hardware. This rigorous testing process is essential for umbrella manufacturing excellence, distinguishing professional umbrella suppliers from those who compromise on quality. Our facility maintains complete transparency and control over every production step.

Our wind tunnel testing facility generates controlled wind speeds up to 100 km/h to test structural integrity and aerodynamic performance. We evaluate frame flexibility, canopy stability, and automatic opening/closing mechanisms under various wind conditions. Our umbrellas are designed to withstand sudden gusts while maintaining their protective function.

Using precision testing equipment, we measure the maximum stress our umbrella components can withstand before failure. This includes testing fabric tear strength, rib joint durability, handle attachment points, and overall structural load capacity. Our umbrellas are engineered to exceed industry standards for mechanical strength and reliability. This level of testing precision is what serious umbrella suppliers demand from their manufacturing partners, ensuring that when customers ask "which company is best for umbrellas" in terms of durability, the answer is backed by scientific data rather than marketing claims.

Our laboratory is equipped with advanced fabric color matching testing instruments to ensure precise and consistent color quality across all fabric batches. Using these devices, we can accurately compare fabric samples with standard color references, evaluate color differences (ΔE), brightness, and hue, and detect even subtle variations. This rigorous testing process guarantees that our products maintain uniform and visually appealing colors, meeting the high expectations of our clients.

Our comprehensive waterproof testing measures hydrostatic pressure resistance and water repellency of umbrella fabrics. We test coating durability, seam sealing effectiveness, and overall water barrier performance. Each umbrella must pass stringent waterproofing standards, ensuring complete protection even in the heaviest rainfall conditions.

Beyond basic waterproofing, we test the water repellency characteristics of our umbrella fabrics using standardized spray tests. We measure how quickly water beads and rolls off the surface, ensuring optimal shedding performance. This testing helps us optimize fabric treatments for superior water management and quick drying times.

Our Steel wool durability testing equipment subjects fabric samples to controlled rubbing cycles that simulate years of normal wear and tear. We evaluate fabric durability, surface integrity, and resistance to pilling or fuzzing. This ensures our umbrellas maintain their appearance and performance throughout their intended lifespan, even with frequent use.

Every Topumbrella product undergoes this comprehensive testing regimen before reaching our customers. Our commitment to scientific validation and quality assurance means you can trust that your Topumbrella will perform reliably in any weather condition, providing years of dependable protection. This is what distinguishes professional umbrella product manufacturing from mass production—attention to detail, rigorous testing, and unwavering quality standards.

As experienced umbrella suppliers serving brands worldwide, we understand that quality testing isn't just about meeting standards—it's about exceeding expectations. When you partner with Topumbrella for umbrella manufacturing, you're choosing a facility that treats every product as a reflection of our commitment to excellence.

Topumbrella Laboratory - Where Quality Meets Innovation

Learn about the international certifications our products hold and how we maintain high quality standards.

Click HereTake a virtual tour of our factory and see the professional production lines and processes.

Click HereLearn more about our umbrella manufacturing operations in Cambodia and our commitment to quality production.

Click Here